MES Solutions

Integrate

An MES that integrates with any ERP

Got an ERP? No worries – AspectPL can integrate with it.

SAP, Microsoft AX, Great Plains, NAV, Syteline, Epicor, SysPro, QAD, Attaché, Consona, Beacon, Greentree, Sage, MYOB, Abel … and many more.

Work orders are automatically extracted from the ERP and dropped into AspectPL for production.

At completion, production data is automatically integrated back into the ERP.

Technical

- Configure specific data fields to link under different export/import scenarios from the ERP.

- Machine connectivity is supported via EtherCAT – an extremely high speed Ethernet network while retaining the more traditional network platforms such as Modbus TCP/IP, Ethernet I/P, I/O link, DeviceNet and hard wired machines.

- Complicated scenarios such as large multi-level BOMs, product dependencies, alternative routings, family tools and multiple classes of products are easily handled once setup.

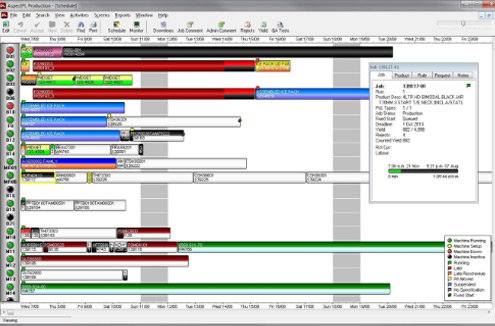

Schedule

Ditch the spreadsheets and create a dynamic, living schedule – in no time.

Cut scheduling time by up to 65%.

Drag and drop work orders into a schedule that is linked to production machines.

Real time production data allows users to monitor and adjust the schedule on the fly.

Technical

- Auto schedule capabilities, allowing a user to schedule a week’s work in a few minutes.

- Manage complex family tools and product dependencies easily.

- Active default dual colour display for products, tools, material classes, tool and colour changes.

- Segmentation of the production facility by department.

- Multiple schedule reports for material picking, tool change preparation, schedule status, resource and material planning.

- Late and overdue job visualization and reporting.

- A Manhattan graph showing actual and required labour resources.

Manufacture

A complete view of manufacturing processes

See live data on manufacturing KPI’s like machine availability, performance and product quality.

Take control of manufacturing and reduce reliance on inaccurate processes like staff data entry.

Because AspectPL is hard wired to production machines on the factory floor, users know the exact machine status at any time. View machine cycle speed, job completion time, volume of items and reject rate.

Technical

- AspectPL is wireless and mobile and reports back work order status, yield, performance and completion dates to the ERP.

- Related documents such as SOP’s, CAD drawings and maintenance records can be linked to production for a paperless environment. Job travellers disappear.

- The combination of works orders and BOM’s with actual production data builds a traceable environment.

- Handles varied production machines and assembly processes on the manufacturing floor.

- High tech German built, Beckhoff Embedded PC Automation Controllers capture machine performance. AspectPL was designed with the ISA-95 standard in mind which facilitates the data exchange between the ERP and MES effectively making the ERP ‘live’.

Insight

Data you can use

Data delivers visibility and certainty – if you know what’s happening on the manufacturing floor you can measure and improve it.

Visibility and traceability enables a regular critique of manufacturing processes, benchmarking progress and measurement of improvements.

More visibility for your business means more easily available information for your customers. Your team can access manufacturing plans and answer customer queries in real time.

Technical

- Measuring Overall Equipment Effectiveness (OEE calculation) is an automatic output of the process managed by AspectPL.

- Quality issues can be traced to (what) job it is, (when) was it produced and (who) packed it.

- Data collection enables actual performance analysis, drill down to root cause analysis and exportable graphs.

- Aligns with and supports company wide Industry 4.0 strategies.

SaaS

No surprises, affordable monthly license fee - which includes technical support

An initial establishment cost and a monthly software license fee make AspectPL very good value. Investment is quickly returned through business efficiencies.

- Licensed per machine, line or workstation – not per user. There is no limit to how many people can be logged on at one time.

- Data helps businesses reduce waste, downtimes and labour costs. It encourages lean manufacturing principles which can increase OEE and net utilisation of machines.

- A new version of AspectPL is released every year. This includes customer requests and ongoing improvements – all included in the monthly license fee.

- AspectPL requires only one PLC controller to interface between the plant and software (not one at every machine). AspectPL uses high-tech and economical Beckhoff Embedded PC Automation Controllers.